Class 7 NCERT Fibre To Fabric Notes Extra

What does “Fibre” signify to you?

Fibers are the continuous, long, fine threads or filaments that come from both plants and animals.

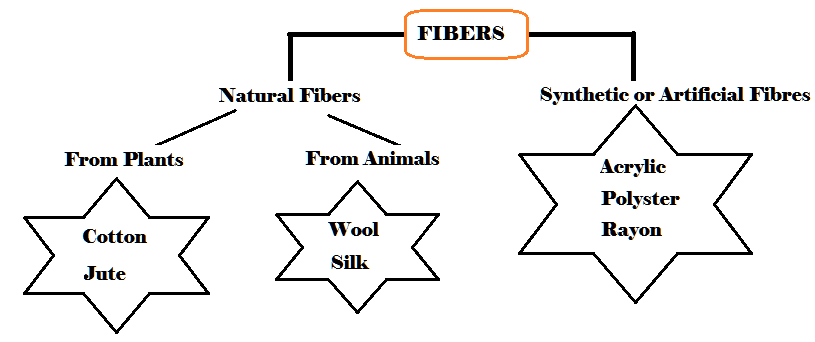

Kinds of Fibers:

Natural Fibers

Natural Fibers are the fibers derived from living organisms, such as plants and animals. Jute and cotton comes under plant-based fibers, whereas silk and wool are examples of animal fibers.

Synthetic Fibers

Synthetic fibers are man-made fibers that don’t exist in the natural world. Rayon, polyester, and acrylic are a few examples.

Kinds of Natural Fibers

(1) Animal Fibers (Silk and Wool)

Wool: The fleece or hair of animals like Angora goats, sheep, alpacas (found in South America), camels, and yaks (found in Tibet and Ladakh) is utilised to make wool. In India, sheep are the primary source of wool. Sheep’s hair is sheared off the body and then goes through a number of processes to produce wool, such as washing, sorting, drying, dying, spinning, and weaving.

Silk: An insect called a silkworm produces silk. A protein fiber that the silkworm secretes during its life cycle solidifies into silk fibers when it comes into touch with air. Silk is a fine, strong, silky, glossy fiber that beetles manufacture during the cocoon-making process. It wraps or shields certain insects while they mature. The silk cloth encircling the cocoon is called a cocoon.

Why is silk cool in summer and warm in winter?

Silk is a good insulator because of its poor heat conductivity. An isolation effect results from the heat being trapped inside between the silk thread. Consequently, the body responds to silk by being warm in the winter and cool in the summer.

Describe Sericulture

A silkworm is a silkworm caterpillar. The practice of rearing silkworms for the purpose of producing silk is known as sericulture. Sericulture is the breeding and cultivation of silkworms for the purpose of producing silk.

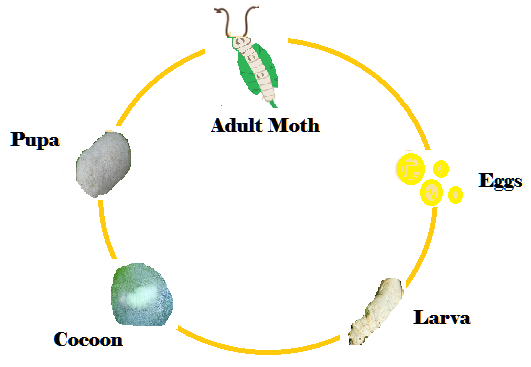

A Silkworm’s life cycle

Four phases of development are experienced by the silkworm:

1. Egg 2. Larva 3. Pupa 4. Adult

Silkworm eggs hatch into caterpillars, often known as silkworm larvae. Silk fiber cocoons are spun by worms at an early stage of their life cycle. A cocoon is the covering that the caterpillar forms into before it transforms into a silk moth. The term “pupa” describes the caterpillar’s subsequent stage of growth. By covering itself in silk, the caterpillar transforms into a cocoon. Proteins are what make up silk strands. After being separated further, the silk fibers from the cocoon are coiled into silk threads. Weavers are given these silk strands to utilize in creating silk fabrics.

NOTE: During the silk moth’s stage of the silkworm life cycle, the caterpillar is completely enveloped in a layer of silk fiber, or a cocoon.

Stage 1: The female silk moth deposits her eggs on mulberry leaves.

Stage 2: The eggs take a week to hatch into small larvae. Then, these larvae feed on the leaves of mulberries. The worm-like larvae are occasionally referred to as caterpillars or silkworms.

Stage 3: At three inches or larger, the caterpillar is ready to transition into the pupa stage of life. A adult silkworm initially weaves a net to support itself. When the protein-based fiber the caterpillar secretes is exposed to air, it solidifies into silk fiber. The caterpillar quickly covers itself from head to toe in silk strands. We refer to this covering as a cocoon. In order to protect itself during the transition into a pupa, the caterpillar builds the cocoon. The caterpillar continues to develop into a silk moth inside the cocoon.

Stage 4: The pupa completely transforms into an adult silk moth during this stage while it is still inside the cocoon. When development is complete, the cocoon splits open to reveal a beautiful silk moth. This concludes the life story of the silk moth.

Why is it not permitted for the pupa to grow into a silk moth?

It’s important to keep in mind that the pupa of the silkworm, which is presently growing inside the cocoon, cannot turn into a silk moth in order to produce silk. This is due to the fact that broken cocoons damage the silk threads, decreasing the quality of the finished product. Therefore, in order to generate high-quality silk thread, the developing silk worm, also known as the pupa, is killed as soon as the cocoon forms.

How silk is made?

The process of producing silk involves raising silk moths and collecting their cocoons to create silk fabric or threads. This is why mulberry trees are produced.

Step1: Growing silk worms in order to harvest their cocoon:

Female silk moths lay hundreds of eggs at a time. These eggs are carefully preserved on paper or fabric strips before being given to silk worm producers. The farmers maintain the proper humidity and temperature conditions to preserve eggs in a hygienic environment.

After that, the eggs are kept at hatching temperature. When eggs hatch, caterpillars or silkworms emerge. Mulberry leaves are subsequently given to the silkworms day and night. Then, their size increases significantly.

The larvae are kept in clean bamboo trays with young, freshly cut mulberry leaves within. After 25 to 30 days, silkworms stop eating and start spinning the cocoon.

Step2: Processing cocoons to make silk fiber:

Boiling the cocoons in water kills the pupa inside. In heated water, the silk fibers of the cocoon separated. Raw silk is the name given to the fiber that is generated.

What is Reeling?

The process of extracting silk fiber from cocoons to make silk is called reeling. The process of reeling involves using specialized equipment to unwind the silk fibers from cocoons.

Step3: Converting silk fiber into silk fabric:

After being taken out of cocoons, the fibers are spun into silk yarn, which is woven into silk fabric by wavers on looms.

How Is Silk Processed?

Silk fibers are collected from cocoons and used in the processing of silk. The cocoons are exposed to sunlight, steam, or boiling water. The silk fibers then split apart after that. The process of extracting thread to make silk from the cocoon is called reeling. Unwinding the silk fibers or threads from the cocoon is called reeling. After then, weavers spin silk fibers into garments.

Wool And Its Origins

Wool is the most widely used animal fiber. Wool is used to make sweaters, scarves, and other woven items.

Wool’s Origins:

Wool is produced from the fleece (hair) of several animals, including camels (found in South America), yaks (found in Tibet and Ladakh), angoras (found in Jammu and Kashmir), goats (found in Kashmir), sheep, and alpacas.

Shearing, grading, carding, and spinning are the several processes that go into processing wool fibre.

Wool-producing animal hair traps a lot of air. Heat does not transmit well through air. Thus, the hairs on these animals protect their bodies from the cold in the winter, keeping them warm.

Wool comes from a wide variety of animals, such as camels, sheep, yaks, goats, and so on.

Describe Shearing

Shearing is the process of taking the fleece off of a sheep or yak in order to obtain wool fiber.

Wool fiber is processed through a number of steps, including shearing, grading, carding, and spinning.

Why do we just remove animal fur once throughout the summer?

Air is trapped by animal hair used to produce wool. Air has a poor ability to transport heat. Therefore, these animals’ hairs keep them warm in the winter by shielding their bodies from the cold.

Because of this, the hair of these animals is only ever cut once a year, at the beginning of summer. Their hair had grown back by the time winter arrives.

Sheep’s fleece with two different types of fiber:

- The unruly facial hair

- The thin under hair (scalp hair that grows in proximity to the skin). These under-hairs are used to make the wool.

How does selective breeding work?

Selective breeding is the process of selecting parents to create offspring with distinctive traits, like sheep with silky underfur.

Describe upbringing.

We mean to provide food, housing, and medical care to sheep, or any other animal for that matter. The persons in charge of taking care of sheep are called shepherds. Mostly, sheep are raised for their wool. They are raised in areas with less rainfall. In India’s plains areas like Haryana, Punjab, Rajasthan, and Gujarat, you can see shepherds guiding their flocks of sheep on a gazing excursion.

Transforming Fibers into Wool

1. Begin with shearing

Shearing is the procedure via which the sheep’s very thin skin and fleece are removed.

2. Next Scouring

In order to remove oil, filth, and grime, sheep’s shorn hair is now cleaned and rinsed in tanks. It then passes thru a series of dryers and rollers.

3. Arrange Hair

In a factory, different types of hair are sorted alongside clean hair.

4. The process of eliminating burrs

Wool has these fluffy, silky fibers. These burrs are removed from the hair completely. Through the use of a machine known as a “carding” machine, the loose wool fibers from the separated hair after the sorting stage are combed into a sheet and then twisted into a rope or silver.

5. Dyeing: The fleece of sheep is normally white, brown, or black. Dyes have been used to color these fibers.

6. Spinning Yarn: In this stage, the wool is combed, straightened, and spun into yarn. After spinning, wool is either woven or knitted. Longer fibers are used to make sweater wool.

7. Now, wrapping the yarn creates enormous woolen balls.

Perils in the Factory (Occupational Hazards)

The risks that workers in any industry face because of the nature of their jobs are known as occupational hazards.

The wool sector employs a large number of people in our country. Sorters, however, are exposed to risk in their line of work since they may become infected with the deadly anthrax bacterium, which causes sorter’s illness.

Plant Fibres

Cotton: One kind of plant fiber produced by the cotton plant is cotton. It thrives in areas with warm temperatures and dark soil. The fruits of the cotton plant, known as cotton bolls, are used to make cotton. The method of separating cotton seeds from cotton fibers is called ginning.

Jute: The stem of the jute plant is the main source of jute fiber. During the wet seasons, it is primarily grown in Assam, West Bengal, and Bihar. When jute plants are in full bloom, they are frequently harvested, and the stems are then let to rot in water. The jute strands must be manually removed from the rotted stalks.

Synthetic Fibers

Man made fibers are called Artificial or Synthetic Fibers such as Polyethylene, Nylon, and Polyster, etc.

Why do winter clothing made of wool keep us warm?

Woolen clothing keeps us warm in the winter because of the wavy growth of wool, a sort of hair. Wool’s waviness gives woolen fabrics greater bulk and air retention than cotton materials. This explains why, on freezing winter days, wearing wool clothing keeps us warm.

Why are sheep not harmed during shearing?

Sheep are safe from injury during shearing since their outermost layer of skin has already died.

What does the phrase “selective breeding” mean?

The process of mating carefully selected parents to create offspring with distinctive features, such soft under-hairs in sheep, is known as selective breeding.